Window Replacement: An Overview of Options and Processes

Outline of the Article

– Why window replacement matters: comfort, efficiency, noise, safety, and curb appeal.

– Frame materials compared: vinyl, wood, fiberglass, aluminum, and composite.

– Glass and glazing choices: double vs. triple pane, coatings, gas fills, and ratings.

– Installation approaches: insert vs. full-frame, steps, code considerations, and timelines.

– Budget, ROI, incentives, maintenance, and how to choose a reliable installer.

– Conclusion: practical next steps tailored to homeowners planning a project.

Why Window Replacement Matters: Comfort, Efficiency, and Everyday Living

Window replacement is one of those projects that you feel as much as you see. New units can quiet a noisy street, calm winter drafts that sneak along the floor, and banish the fog that forms on cold panes at dawn. Beyond comfort, thoughtful upgrades can reduce heating and cooling loads, stabilizing indoor temperatures so your HVAC system works less. While results vary by climate, home age, and the windows being replaced, households often report single‑digit to low double‑digit reductions in energy use when moving from leaky single‑pane or aging double‑pane units to modern, well‑installed assemblies. That kind of savings compounds over years, especially in regions with long heating or cooling seasons.

Comfort has multiple layers. Thermal comfort improves when frames and glass reduce conduction and drafts; visual comfort rises with clearer glass and better daylight management; acoustic comfort benefits from thicker glass or laminated layers that dampen traffic noise. Safety and resilience also step up: tempered glass in required locations resists shattering hazards, and new locks and sturdier frames contribute to a more secure envelope. In bedrooms and basements, properly sized operable windows support emergency egress, a critical code requirement that older homes sometimes miss.

It is easy to focus on style alone, but performance is where the daily dividends live. Two key metrics guide informed choices. U‑factor describes how readily heat flows through the entire window assembly; lower values indicate stronger insulation. Solar Heat Gain Coefficient (SHGC) tells you how much solar energy passes through the glass; a lower number blocks more sun heat, helpful in hot climates, while a moderate value can be beneficial in cooler regions where winter sun is welcome. Choosing the right combination for your climate yields a quieter, more stable, and more efficient interior. Alongside performance, replacement can refresh curb appeal with cleaner sightlines and consistent finishes, which can support resale value when paired with quality installation.

For quick orientation, consider these homeowner goals that window replacement can address: improved comfort during temperature extremes; a noticeable drop in drafts; fewer condensation issues; better daylight without glare; quieter rooms; and smoother, safer operation. Matching these goals to materials, glazing, and installation method sets the foundation for a successful project and helps you prioritize where to invest.

Frame Materials Compared: Vinyl, Wood, Fiberglass, Aluminum, and Composite

The frame is the backbone of a window—shaping durability, maintenance needs, thermal performance, and aesthetics. Different materials carry different trade‑offs, and no single option fits every house or climate. Understanding the characteristics of each helps you choose with intention rather than guesswork.

Vinyl is a widely chosen option because it balances cost, insulation, and low maintenance. It resists rot, never needs repainting, and can offer competitive U‑factors when paired with quality glazing. On the flip side, budget vinyl can expand and contract more noticeably with temperature swings, and color choices may be limited. For many homes, vinyl delivers practical comfort at a value‑minded price point, especially in standard sizes and styles.

Wood remains a favorite for those seeking warmth, traditional profiles, and excellent natural insulation. Properly finished, wood looks refined and works well in historic homes. The trade‑off is upkeep: periodic painting or staining and vigilant moisture management are essential to prevent rot or swelling. In harsh climates or salt‑air environments, maintenance diligence becomes even more important. Many homeowners choose wood where authenticity matters, then manage maintenance with scheduled touchups.

Fiberglass offers a well‑regarded mix of strength, dimensional stability, and thermal efficiency. It expands and contracts at rates closer to glass, helping maintain seals over time. Frames tend to be slim yet rigid, enabling broader views without sacrificing performance. Fiberglass can be finished in factory colors and generally needs less attention than wood, though it comes at a higher upfront cost than standard vinyl.

Aluminum frames shine for their slim profiles, structural strength, and suitability in modern designs with large openings. Historically, aluminum conducted heat readily, but thermal breaks have improved performance. Even so, in very cold climates, aluminum may trail other materials on U‑factor unless paired with advanced glazing and careful installation. In warm or mixed climates where strength and slender sightlines are priorities, aluminum can be compelling.

Composite frames combine materials—often wood fiber and polymers—to deliver stable performance with reduced maintenance. They aim to capture wood’s look with improved resistance to moisture and temperature shifts. Composites are typically priced in the mid to upper range and can provide a strong balance of durability and energy efficiency. As with any material category, quality varies by manufacturer and product line, so review performance ratings rather than assuming all composites behave the same.

Typical installed price ranges vary by region, size, and scope, but general patterns hold: vinyl often sits at the more affordable end; aluminum and some composites occupy the middle; fiberglass and high‑grade wood trend higher. Regardless of material, glazing quality and installation skill can influence performance as much as the frame choice. For decision‑making, line up goals against traits: prioritize low maintenance and cost stability with vinyl; lean toward authentic appearance and insulation with wood; choose fiberglass for balanced strength and efficiency; pick aluminum for structural demands and modern aesthetics; turn to composites for a hybrid approach that reduces upkeep while maintaining a refined look.

Glass and Glazing Choices: Getting Clarity on Performance

While frames set the structure, glass does the heavy lifting on comfort and efficiency. Most replacements today use sealed insulating glass units—two or three panes separated by spacers, with air or inert gas between them. Double‑pane assemblies are common and can deliver strong performance when paired with low‑emissivity coatings. Triple‑pane options add a third layer that can further lower U‑factor and boost winter comfort, especially in cold regions, though they can add weight and cost.

Low‑emissivity (low‑E) coatings are microscopically thin metal layers that manage heat transfer. In heating‑dominant climates, coatings that reflect indoor heat back into the room while allowing winter sun in can be helpful. In cooling‑dominant climates, coatings that reduce solar heat gain can keep interiors cooler and mitigate fading of furnishings. You will also see ratings that matter in everyday use: U‑factor (lower is better insulation), SHGC (lower blocks more sun heat), and Visible Transmittance (higher means more daylight). Balancing these numbers prevents a common pitfall: chasing the lowest SHGC everywhere and ending up with darker interiors than intended.

Gas fills improve performance by slowing convection between panes. Argon is widely used for its strong cost‑to‑benefit profile; krypton appears in narrower airspaces, often in triple‑pane units. Spacer technology also matters: warm‑edge spacers reduce heat transfer at the glass perimeter, helping with condensation resistance near the edges. Speaking of condensation, no window can change indoor humidity all by itself, but higher‑performing glazing and well‑sealed frames can reduce cold‑edge sweating and the streaks that follow.

Acoustics are a quieter hero. Even without specialized products, moving from single‑pane to double‑pane often improves sound control. For busy streets, consider laminated glass in at least one pane; the interlayer dampens vibrations and raises the Sound Transmission Class (STC) rating. As a simple guide: around the upper 20s STC feels modest; the low to mid‑30s can noticeably soften traffic; higher numbers improve privacy in dense neighborhoods. For even performance, mixing pane thicknesses can spread out resonance peaks, smoothing noise reduction across different frequencies.

Safety glazing is required in certain “hazardous locations,” such as near doors, in large panels close to the floor, or in wet areas. Tempered glass crumbles into small pieces when broken, reducing injury risk; laminated glass holds together if cracked. If you are replacing windows in a bath, stair landing, or next to a door, verify whether safety glazing is needed. Finally, climate‑savvy selection pays dividends. Colder regions often benefit from lower U‑factors and moderate SHGC on south exposures; hot, sunny climates tend to prioritize lower SHGC to control heat gain. Matching glass packages to orientation—south, east, west, north—can fine‑tune comfort throughout the day.

Installation Approaches: Insert vs. Full-Frame and How the Process Works

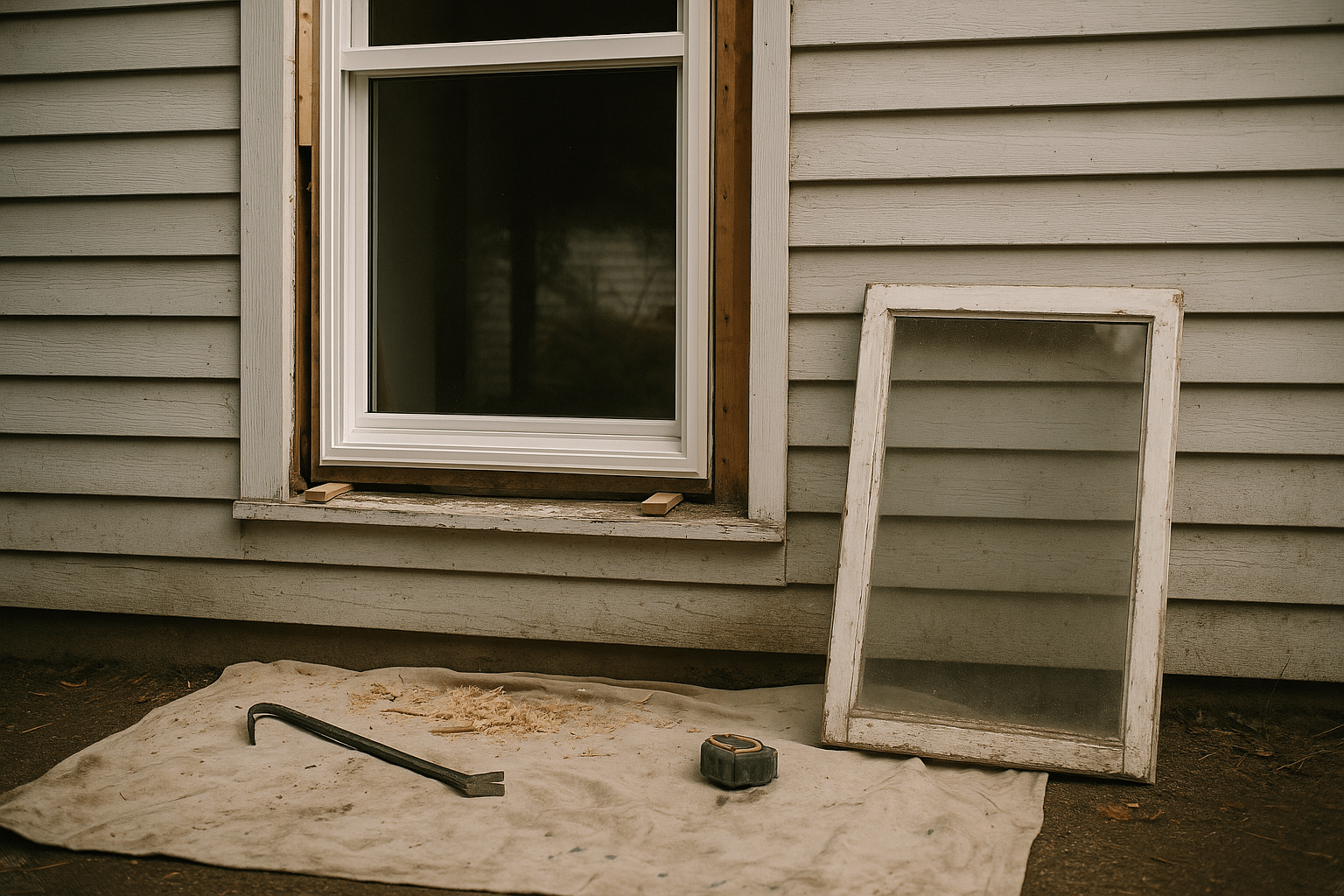

Even the most efficient window underperforms if installed poorly. Two main approaches dominate replacement: insert (also called pocket) and full‑frame. Insert installation fits a new window into the existing frame after removing the old sashes. It preserves interior and exterior trim, reduces disruption, and can be quicker and more economical. The trade‑off is that you keep the old frame; if it is out of square, rotted, or poorly insulated, performance gains may be limited.

Full‑frame replacement removes the entire window assembly down to the rough opening. This allows inspection of the sill and studs, correction of water damage, and installation of new flashing and insulation. It is more involved and can require new interior casing and exterior trim or cladding, but it provides a clean slate. When rot, water intrusion, or severe air leakage is present, full‑frame is often the more durable path.

A quality installation follows a measured sequence: accurate measurements; protection of interiors; careful removal of old components; preparation of the opening with flashing and a sloped sill pan to direct water out; dry‑fitting the new unit; setting with shims for level and square; fastening per manufacturer guidance; sealing the perimeter with low‑expansion foam and backer rod with sealant; and finally, integrating exterior flashing with the water‑resistive barrier. On the inside, gaps are insulated and trims restored. On the outside, head flashing and sill details manage wind‑driven rain. Small choices matter: foam that expands too aggressively can bow frames; sealants must be compatible with adjacent materials; and shims should be placed at structural load points, not just anywhere they fit.

Codes and safety considerations deserve attention. Bedrooms require operable egress windows of sufficient size; local rules also govern tempered safety glass near doors and in baths. In older homes, particularly those pre‑dating certain paint regulations, safe work practices help manage dust when disturbing painted surfaces. Permits may be required, especially when changing sizes or framing. A good installer will handle these details and explain the plan up front.

Homeowners often ask about timelines and disruption. Insert installations frequently finish in a few hours per opening; full‑frame can take longer, especially with exterior cladding or interior finish work. Weather can extend schedules, as sealants and paints have temperature limits. Clear communication reduces surprises. Request a written scope, including how openings will be protected if work stretches overnight, how debris will be handled, and what happens if hidden damage is discovered. A calm, documented process turns a dusty day into a lasting upgrade.

Budget, ROI, Incentives, Maintenance, and Choosing a Reliable Installer

Planning the budget starts with framing material, glazing package, size, and installation approach. Insert replacements in standard sizes usually cost less than custom full‑frame projects. As a rough orientation rather than a promise, homeowners often see installed costs per opening ranging from the lower hundreds for simple vinyl inserts to the upper hundreds or beyond for larger fiberglass, composite, or wood units with advanced glass. Specialty shapes, complex mulled assemblies, or extensive trim work will add to the total. Labor rates vary by region and season, and access matters—second‑story or masonry openings can require extra time and equipment.

Return on investment shows up in multiple ways. Energy savings accumulate month by month; comfort improvements are immediate; and curb appeal supports resale. Industry surveys have long observed that mid‑range window projects commonly recoup a meaningful portion of cost at resale, often in the broad band around the middle of the spectrum for exterior upgrades. Real outcomes depend on local markets, house condition, and the quality of both product and installation. Think in terms of lifetime value rather than quick payback alone: durable materials, correct flashing, and climate‑appropriate glazing protect walls, finishes, and furnishings for years.

Incentives can help. Many utilities and governments periodically offer rebates or tax credits for certified energy‑efficient windows, often tied to specific performance thresholds for U‑factor and SHGC. Programs change frequently, so verify current requirements before you buy, and keep documentation for submissions. Some incentives apply only to primary residences, and many require installation by a licensed contractor. Combining a moderate rebate with long‑term energy savings can move a project from “someday” to “soon.”

Maintenance planning keeps new windows performing smoothly. Clean weep holes at the sill to prevent water buildup; check exterior sealant joints annually; wash glass and frames with non‑abrasive cleaners; and operate sashes periodically to keep balances and locks moving freely. Painted wood needs routine inspection and touchups; aluminum and fiberglass benefit from gentle cleaning and occasional hardware lubrication; vinyl appreciates clean tracks and protection from harsh solvents. Small, consistent care extends service life and preserves appearance.

Choosing a reliable installer may be the single most important decision. Compare multiple written proposals with clear scopes. Ask about training, years in business, and how crews handle flashing, sill pans, and warranty service. Read recent, verified reviews and request local references you can visit from the sidewalk. Ensure proposals include product performance ratings, installation method, exterior integration details, and cleanup. Red flags include vague language, unusually low bids without explanation, and pressure to skip permits or inspections. A dependable pro will welcome your questions, provide insurance and license documentation, and explain what happens if unexpected framing issues appear once the old units come out.

Conclusion: A Clear Path to Comfortable, Efficient Windows

Window replacement rewards careful planning. Start by defining goals—comfort, energy, sound control, style—then match materials and glazing to your climate and home. Choose an installation approach that addresses any underlying issues, and partner with a contractor who explains flashing, sealing, and code requirements in plain terms. With a balanced plan, you gain quieter rooms, steadier temperatures, and a refreshed look that serves you every day, season after season.