Local AC and Heating Repair Services in the Netherlands: A Practical Guide to Maintenance and Repairs

Why Local AC and Heating Repair Matters in the Dutch Climate (Outline + Introduction)

The Netherlands lives in the space between the sea and the sky: damp winters, breezy shoulders seasons, and a handful of warm, sticky summer spells. That mix means indoor comfort is not a luxury; it is a steady project. Repairs and maintenance keep hydronic radiators warm without clanging, heat pumps defrosting efficiently, ventilation systems exchanging air without drafts, and compact air conditioners dehumidifying without short cycling. In short, understanding how local specialists work helps households avoid emergencies and protect energy budgets. This section sets the stage and offers the outline for the rest of the guide, anchored by the practical lens of Understanding AC and Heating Repair Services in the Netherlands.

Outline of what you will learn:

– Section 1 (this section): Climate context, common Dutch systems, and what “repair” really covers

– Section 2: An Overview of Local HVAC Maintenance and Repair Practices, including seasonal checklists

– Section 3: How Heating and Cooling Repairs Support Comfort in Dutch Homes, with examples on humidity, noise, and airflow

– Section 4: Key Considerations When Seeking AC or Heating Repairs in the Netherlands, from certifications to guarantees

– Section 5: A seasonal action plan, budget pointers, and a conclusion aimed at homeowners, tenants, and small building managers

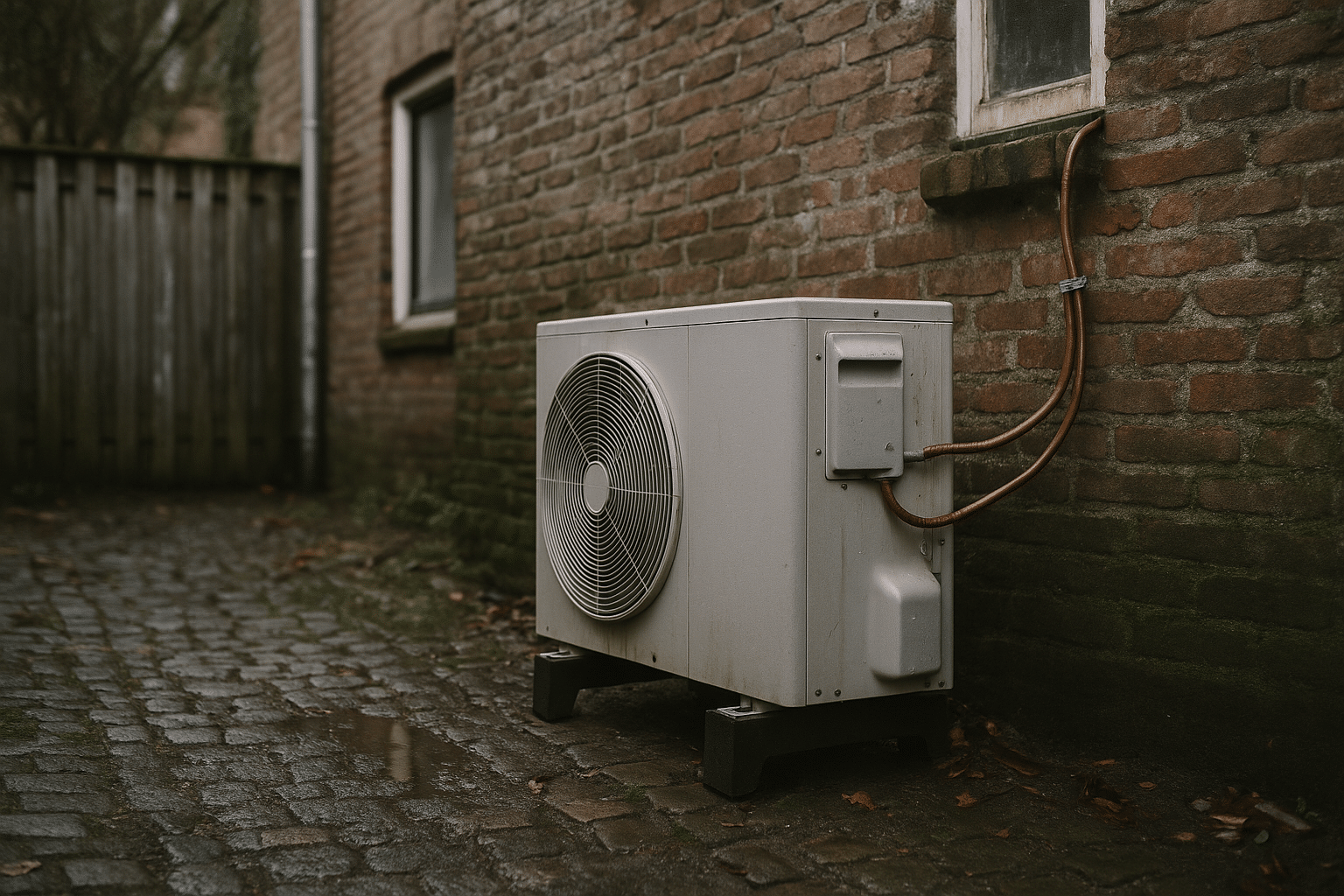

Across the country, you will encounter four system types most often: gas-fired or district-heated hydronic systems, air-to-water or air-to-air heat pumps, mechanical ventilation with heat recovery in tighter buildings, and compact split or multi-split cooling for lofts and top-floor flats. Repairs range from quick fixes (filter changes, thermostat calibration) to safety-critical work (combustion testing, refrigerant leak resolution). Because Dutch homes are increasingly energy-tight, correct airflow and humidity control matter as much as raw heating power. Technicians who know local building quirks—older brick canal houses, post-war blocks with panel radiators, and newer low-energy homes with underfloor heating—can diagnose the root cause rather than chase symptoms.

Data points help frame decisions without hype. Heat pump systems often deliver seasonal performance factors between roughly 3 and 4 when properly sized and maintained, meaning each unit of electricity can yield multiple units of heat across the season. Summer comfort hinges on sensible dehumidification as much as air temperature; keeping indoor relative humidity around 40–60 percent typically feels comfortable while discouraging condensation and mold. Routine, local repair and maintenance keep these targets achievable while preventing minor issues—like a clogged condensate line or a sticking radiator valve—from becoming expensive outages on the coldest or muggiest days.

Reliable Routines: An Overview of Local HVAC Maintenance and Repair Practices

Good repair work starts long before something breaks. An Overview of Local HVAC Maintenance and Repair Practices focuses on predictable routines that reduce risk and stabilize operating costs. In the Dutch context, preventative schedules usually align to the seasons: a spring check before cooling demand, and an autumn tune-up before heating season. The goal is to ensure airflow, water flow, and refrigerant circuits perform to spec, insulation remains intact, and controls respond steadily.

What a routine visit commonly includes:

– Cooling systems: Clean or replace intake filters, rinse indoor and outdoor coils, clear the condensate line, check fan motor amperage, verify refrigerant charge by subcooling/superheat or manufacturer tables, and confirm temperature split across the evaporator

– Hydronic heating: Bleed radiators or manifolds, confirm pump operation and differential pressure, test expansion vessel pre-charge, inspect safety valves, check for sludge and consider a magnetic filter or system flush if circulation is uneven

– Heat pumps: Inspect defrost cycle logic, clean outdoor coils of salt and debris common in coastal air, check vibration mounts, and verify sensor readings for ambient and coil temperature

– Ventilation with heat recovery: Replace filters, inspect heat exchanger cores for dust buildup, and balance supply/exhaust flows to avoid pressure imbalances

Compliance is not just paperwork—it’s safety. Technicians handling refrigerants follow EU F-gas rules and hold relevant certifications; heating work should include combustion analysis for gas appliances and flue inspection to prevent backdrafting. Proper waste handling for oils, filters, and refrigerant-recovery cylinders ensures environmental responsibility. Documentation matters: a clear report noting measurements (air temperature differentials, pressure readings, electrical tests) gives you a baseline for future diagnosis and warranties. When something does fail, that paper trail speeds up repair decisions and helps distinguish between component aging and install errors.

Practical tip: small adjustments multiply. For cooling, a clean filter maintains airflow, which protects the compressor against icing and short cycling. For heating, correctly set thermostatic radiator valves prevent rooms from overshooting and reduce pump strain. For ventilation, timely filter swaps preserve heat recovery effectiveness, which supports winter comfort and indoor air quality. The outcome is not only fewer breakdowns but quieter, more stable operation that feels effortless day-to-day—a hallmark of competent local maintenance.

Comfort, Quiet, and Air You Trust: How Heating and Cooling Repairs Support Comfort in Dutch Homes

Comfort is a layered experience: temperature, humidity, airflow, sound, and even smell. How Heating and Cooling Repairs Support Comfort in Dutch Homes is best understood through common scenarios. A top-floor apartment may cool quickly but feel clammy because the unit short cycles; a simple fix like cleaning coils, improving condensate drainage, and recalibrating fan speeds can restore steady dehumidification. An older terraced house with mixed radiators may be warm upstairs and chilly downstairs; balancing valves, a pump speed adjustment, and a targeted system flush can make the whole home feel even without cranking up the thermostat.

Humidity control deserves special attention in the Dutch climate. Coastal winds and frequent rain raise outdoor moisture; indoors, cooking and showering add more. Keeping relative humidity roughly in the 40–60 percent band reduces condensation on cold surfaces and inhibits mold growth. Technicians achieve this by ensuring dehumidification cycles run long enough, improving duct or room airflow, and sealing stray air leaks that pull in damp outdoor air at the wrong points. In houses with mechanical ventilation, filter health and balanced flows maintain fresh air without robbing heat in winter or allowing excess moisture in summer.

Noise and drafts are comfort saboteurs. Repairs that secure fan housings, replace worn bushings, and isolate vibrations turn a rattling unit into a background whisper. For hydronic systems, eliminating air pockets and adjusting valve authority reduces water hammer and ticking pipes. When service teams take the time to check every connection—from the thermostat location to the slope of a condensate line—the result is fewer nuisances and a calmer home. The difference shows up at night: rooms stay closer to setpoint, and equipment cycles less often.

Energy performance benefits follow. A correctly charged cooling system with clean coils and unblocked airflow can deliver more cooling per watt, while a tuned hydronic system with the right flow temperature supports low-temperature operation—helpful for efficiency and for underfloor loops. Over a season, these incremental improvements help moderate bills and shrink the home’s carbon footprint. Just as important, they reduce surprise breakdowns during a cold snap or the first hot spell of summer, which is when call volumes spike and appointment windows tighten.

Choosing a Local Service With Confidence: Certifications, Quotes, and Guarantees

The market is crowded, but a structured approach cuts through the noise. Key Considerations When Seeking AC or Heating Repairs in the Netherlands begin with qualifications. Refrigerant work requires certified personnel and companies under EU F-gas regulations; heating work benefits from recognized installer certifications, sound combustion testing practices, and up-to-date safety training. Ask for proof of competence and do not be shy about requesting sample service reports—professionals expect it and will gladly explain their measurement methods.

How to evaluate a proposal without guesswork:

– Scope clarity: Look for itemized tasks (diagnostics, parts, labor, testing) and clear exclusions (access issues, additional materials)

– Evidence-based diagnostics: Good reports cite measurements—pressure, temperature, airflow, electrical readings—rather than vague “topped up gas” notes

– Warranty terms: Understand what is covered, for how long, and whether it includes workmanship or only parts

– Response and availability: Note typical lead times in peak seasons and whether emergency callouts are offered

– Safety and compliance: Confirm leak testing, recovery procedures for refrigerant, and flue/condensate checks on combustion appliances

– Data etiquette: Respect for your home includes leaving operating settings documented and explaining changes before departing

Price matters, but value is multi-dimensional. A slightly higher hourly rate can be offset by fewer callbacks if the team works systematically and documents findings. Local familiarity with Dutch building envelopes—insulated façades, cavity walls, and tight upper floors—often translates into faster root-cause analysis. Clear communication is another hallmark: technicians who walk you through what failed, why it failed, and how to avoid repeat issues turn a repair into a learning moment. Over time, these conversations help you plan upgrades, like adding weather compensation to a boiler or optimizing heat pump setpoints for low-temperature radiators or floors.

Finally, compatibility and parts availability deserve a look. Many homes blend older radiators with newer heat sources or include ventilation units from different eras. A capable service partner checks control logic across devices, ensures sensors read truthfully, and confirms that common-wear parts are reasonably available. That forethought keeps a minor component failure from turning into a prolonged outage, especially during the first cold week when everyone else is calling for help.

Seasonal Action Plan, Budget-Savvy Tips, and Conclusion for Dutch Households

A practical calendar makes maintenance manageable. Think in seasons and match tasks to what the weather is likely to demand.

– Spring: Schedule a cooling and ventilation check; clean filters and coils; test condensate drainage; verify shading and blinds to reduce solar gain

– Summer: Monitor indoor humidity; if rooms feel sticky, ask for a fan-speed or cycle-length review to improve dehumidification; keep outdoor units free of leaves and seed fluff

– Autumn: Bleed radiators, test circulation pumps, inspect expansion vessels, and set thermostatic radiator valves to consistent baselines for even heat

– Winter: Check for drafts around window frames, ensure ventilation filters are fresh to reduce stale air without losing too much heat, and listen for changes in equipment sound that hint at wear

Budget does not have to be mysterious. Grouping tasks into biannual visits keeps costs predictable and helps you claim minor rebates where available through local programs. Small investments—like a magnetic filter on a sludgy hydronic loop or a condensate safety switch on an attic air handler—can prevent larger failures. If you are planning an upgrade, ask your technician to simulate setpoint strategies for your mix of emitters (radiators, convectors, or underfloor) to see whether a lower flow temperature is practical. Lower temperatures can improve efficiency and comfort by reducing overshoot and surface temperature swings.

Repairs are also a chance to build resilience. A careful service call will check freeze protection on heat pumps, confirm that defrost cycles are clearing frost efficiently in damp cold, and verify that thermostats are placed away from drafts and sunlight. In summer, targeted adjustments to airflow and staged cooling guard against humidity spikes that trigger mold growth. Documenting each visit—photos of coil condition, readings of pressure and temperature, and serial numbers—creates a maintenance dossier that helps when selling or renting the property, signaling that the systems are cared for and performing as intended.

Conclusion: Dutch homeowners, tenants, and small building managers benefit most when they treat HVAC care as an ongoing partnership rather than a fire drill. Local pros understand the climate, the housing stock, and the way modern systems interact in tight, energy-conscious buildings. By following the seasonal plan above, insisting on clear diagnostics, and aligning repairs with efficiency goals, you can extend equipment life, stabilize comfort, and make each kilowatt-hour work harder. If you keep the guidance in this guide close—especially the sections on Understanding AC and Heating Repair Services in the Netherlands, An Overview of Local HVAC Maintenance and Repair Practices, How Heating and Cooling Repairs Support Comfort in Dutch Homes, and Key Considerations When Seeking AC or Heating Repairs in the Netherlands—you will be well-prepared for the next cold snap or heatwave, with fewer surprises and a calmer home.