Industrial Machines: How They Work and Where They Are Used

Outline

– Working principles: power, motion, and control

– Machine families: cutting, forming, molding, and additive

– Material handling: conveyors, robots, and mobile systems

– Control, sensing, and safety fundamentals

– Where machines are used and how to choose wisely

From Power to Precision: The Working Principles Behind Industrial Machines

At their core, industrial machines convert energy into controlled motion to perform repeatable work with accuracy and speed. That sentence hides a universe of physics and engineering. Power typically enters as electricity, pressurized fluids, or combustion, and actuators translate that power into movement—rotational, linear, or a mixture of both. Electric motors dominate modern plants due to their high efficiency (often 90–97% for premium units) and controllability. Hydraulics provide high force density for presses, lifts, and heavy-duty tasks, with typical overall system efficiencies around 75–85% when well maintained. Pneumatics are lightweight and fast, excellent for pick-and-place or eject operations, though they can be energy hungry; only a fraction of compressor input ends up as useful mechanical work, which is why air leaks are treated like emergencies in lean plants.

Between power and the tool sits transmission and motion control. Gears, belts, ballscrews, and linear guides shape torque and speed into the specific motion a process needs. Position and speed are governed by control loops: sensors provide feedback, a controller compares actual to target values, and a drive or valve adjusts output. Modern servo systems can hold position within micrometers under the right conditions, but every machine balances precision with stiffness, thermal expansion, and load variations. Heat is the quiet saboteur—warm components expand, altering clearances—so designs include cooling circuits, thermal compensation, and sometimes warm-up cycles that stabilize geometry before production ramps up.

To understand how machines achieve reliable precision, think in layers:

– Energy: incoming electricity, compressed air, or hydraulic pressure.

– Actuation: motors, cylinders, pumps turning energy into motion.

– Transmission: gears, couplings, screws, bearings directing force.

– Sensing: encoders, pressure transducers, temperature probes, vision.

– Control: algorithms that correct errors in real time.

– Interface: simple buttons, touch panels, or integrated dashboards.

When those layers are coordinated, a machine becomes a dependable metronome: start, move, cut, measure, repeat. And like a metronome, the rhythm matters—cycle times, acceleration ramps, and dwell periods are tuned so parts come out consistent, hour after hour.

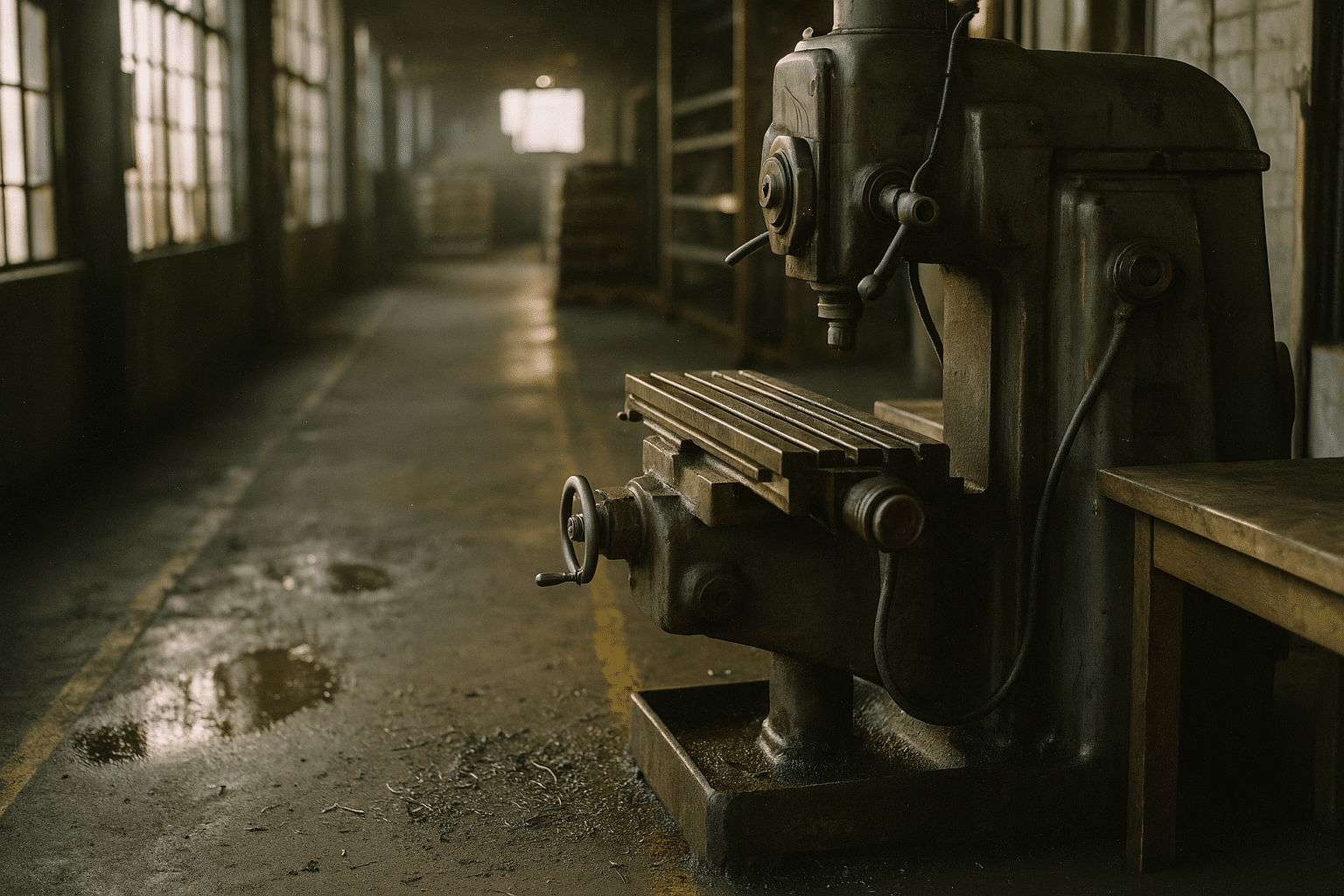

Cutting, Forming, and Shaping: A Tour of Major Machine Families

Industrial machines earn their keep by changing the shape, properties, or placement of materials. In subtractive processes, cutters remove material to achieve a final geometry. Typical examples include turning, milling, drilling, grinding, and waterjet or plasma systems that profile sheet and plate. Metal-cutting accuracy can reach tolerances of ±0.005 mm in controlled environments, while surface finishes can be tuned from functional to mirror-like depending on tooling, speed, and coolant strategy. Cutting parameters trade off speed against tool life and heat; doubling cutting speed may dramatically raise heat generation, which is why coolant delivery, chip evacuation, and spindle power are carefully balanced.

Forming processes reshape material without removing it. Press brakes bend sheet metal; stamping presses form parts at strokes per minute that sound like a heartbeat; roll formers gradually bend long strips into complex profiles with remarkable consistency. Force capacity is rated in tons, with mid-size machines frequently operating in the 50–400 ton range. Forming avoids chips, often reduces waste, and can strengthen parts via work hardening. In molding and casting, molten or softened material fills a cavity: thermoplastic injection molding routinely achieves cycle times of 10–60 seconds for small parts, while extrusion pushes continuous profiles—think seals, tubes, and siding—with tight dimensional control maintained by temperature and puller speed.

Additive manufacturing builds parts layer by layer from powders, wires, or resins. Though often associated with prototypes, it is now used for jigs, fixtures, and select production components, especially when internal channels, lattice structures, or short-run customization bring value. Layer thicknesses range widely—tens of micrometers for fine polymer or metal powder processes, to millimeters for large-format deposition—so additive shines where geometry complexity outweighs the need for ultra-high throughput. A practical comparison:

– Cutting: high accuracy, strong materials, chip waste, mature workflows.

– Forming: fast for large volumes, material-efficient, tooling upfront cost.

– Molding/Casting: excellent for complex shapes in high volumes, depends on mold quality.

– Additive: design freedom, low tooling cost, slower per-part in many cases.

The right choice depends on volume, tolerance, material, and total cost of ownership rather than a single metric.

Moving Materials Efficiently: Conveyors, Robots, and Mobile Systems

Production is more than shaping parts—it is also about getting them to the right place at the right time. Conveyors provide the backbone of flow. Belt conveyors move cartons and parts with gentle handling; roller conveyors enable accumulation and zero-pressure zones to avoid collisions; slat and chain designs carry hot or oily components that would defeat a standard belt. Throughput is governed by belt speed, load spacing, and merge/divert logic; even modest lines can exceed thousands of units per hour when properly balanced. Sensors along the line prevent jams, while guide rails and fixtures keep products oriented for downstream operations.

When flexibility or precision handling is needed, multi-axis machines shoulder the load. Industrial robots repeat motions with repeatability as fine as ±0.02 mm under controlled conditions, making them suitable for electronic assembly, machine tending, and precision dispensing. Articulated arms excel at complex paths, while delta and SCARA configurations deliver blinding speed for lightweight pick-and-place. End-of-arm tooling—grippers, vacuum cups, magnetic pads, or custom nests—transforms a general-purpose mover into a process specialist. For staging between islands of automation, automated guided vehicles and autonomous mobile robots carry pallets or totes, navigating via markers, natural features, or maps. Typical payloads span from tens of kilograms to over a ton, and fleet management software keeps traffic smooth so aisles don’t become bottlenecks.

Overhead, cranes and hoists lift where floor space is precious or loads are unwieldy. Jib cranes serve workcells, gantry cranes straddle large fixtures, and bridge cranes sweep across bays. The selection calculus looks like this:

– Distance and path: fixed lanes favor conveyors; varied routes favor mobile units.

– Payload and precision: heavy and awkward may call for cranes; light and precise suits robots.

– Throughput variability: buffers and accumulation help absorb surges without over-sizing every machine.

– Environment: heat, dust, washdown, and cleanroom rules narrow the options.

Even simple adjustments—smoother merges, smarter accumulation, ergonomic handoff heights—often unlock more throughput than adding another machine. In short, material handling is the quiet multiplier of productivity, and its design determines whether a plant hums or hiccups.

The Brains and Senses: Control, Feedback, and Safety You Can Trust

What makes a machine reliable is not just steel and horsepower but the intelligence that guides them. Controllers coordinate I/O, motion profiles, and interlocks, while drives or valves translate digital commands into physical response. Variable-frequency drives tailor motor speed to load, saving energy on fans and pumps; servo drives add precise torque and position control for axis-by-axis choreography. Networks knit everything together: fieldbuses and Ethernet-based protocols connect sensors, actuators, and controllers with deterministic timing so that a millisecond means exactly a millisecond. In production, timing predictability is as important as speed because it allows multiple machines to synchronize without queue chaos.

Sensors are the eyes and ears of automation. Common types include:

– Position and motion: encoders, resolvers, linear scales, proximity switches.

– Process: pressure, temperature, flow, humidity, and force transducers.

– Vision: 2D cameras for presence and alignment; 3D sensors for bin picking and inspection.

– Condition: vibration, current, and acoustic sensors for predictive maintenance.

With feedback in place, closed-loop control maintains quality in the face of disturbances like tool wear, temperature drift, or variable material. Data from these sensors feeds dashboards and historians, enabling operators to spot trends and intervene before a minor deviation becomes scrap or downtime. Even simple metrics—overall equipment effectiveness, changeover time, energy per unit—give teams powerful levers to improve output and cut waste.

Safety is engineered, not just bolted on. Guarding, interlocks, light curtains, and emergency stops are integrated into safety-rated circuits designed to meet functional safety targets. Risk assessments consider severity, exposure, and avoidance; the resulting architecture might include dual-channel inputs, monitored safety relays, or safety controllers with diagnostics. Standards guide the process, and regular validation ensures changes do not erode protection. Cybersecurity matters too: segment networks, manage user roles, and keep firmware current so that connected machines stay trustworthy. When people, product, and equipment share space, the safest workflow is the one that is intuitive—clear status lights, consistent naming, and logical layouts reduce surprises and keep attention where it belongs.

Where They Are Used: Sector Snapshots and a Practical Playbook for Decisions

Industrial machines anchor almost every sector that produces the physical world. In discrete manufacturing, cutting and forming teams deliver frames, enclosures, and precision components, while robots handle assembly, dispensing, and testing. In process industries, pumps, mixers, and separators maintain tight control over viscosity, temperature, and purity to meet regulatory requirements. Food and beverage plants rely on washdown-rated conveyors, hygienic filling lines, and gentle handling to protect product quality. Energy sectors deploy turbines, compressors, and grid-scale switchgear with monitoring systems that track vibration, temperature, and load to extend service life. Construction materials rely on kilns, crushers, and classifiers; agriculture uses harvesters and automated packing lines; logistics hubs orchestrate sortation and palletizing at daunting volumes.

Choosing machinery is both technical and strategic. A practical playbook:

– Define the requirement: volume, tolerance, takt time, and flexibility targets.

– Map constraints: power, air, water, floor space, and environmental conditions.

– Evaluate process fit: compare cutting vs. forming vs. molding vs. additive based on material and lifecycle cost.

– Quantify risk: availability of skills, spare parts, and vendor support; training load for operators and technicians.

– Model total cost: energy, maintenance, consumables, and changeover time, not just purchase price.

– Pilot and iterate: start with a critical cell, measure outcomes, and scale based on data.

Maintenance locks in value. Preventive schedules handle lubrication, filtration, and alignment before wear cascades into failures. Predictive techniques—vibration spectra, thermal imaging, oil analysis—spot anomalies early, turning unplanned stops into scheduled micro-downtime. Many plants report double-digit percentage reductions in downtime after adopting basic condition monitoring, not because they installed exotic gear, but because they acted on small patterns consistently.

Sustainability and resilience now shape decisions alongside throughput. Reducing compressed air leaks can save substantial energy; choosing higher-efficiency motors lowers lifetime electricity use; heat recovery on ovens or compressors can preheat incoming air or water. Designing for modularity eases upgrades, so a cell can adapt to new products without ripping out the floor. The final check is people: intuitive interfaces, clear work instructions, and thoughtful ergonomics reduce training time and errors. Machines multiply human capability; the craft lies in aligning capability with real constraints so operations remain agile when demand shifts or supply chains wobble.