Understanding Plumbing Systems in the United States: Water Supply, Drainage, and Key Components

Outline

– Foundations: public health, infrastructure links, and energy implications

– Homes versus workplaces: loads, risk profiles, and maintenance approaches

– Flow mechanics: pressure, distribution, drain-waste-vent behavior, and regional factors

– Hardware and design: materials, safety devices, and performance benchmarks

– Action plan: practical steps, budgeting, and collaboration with licensed professionals

The Big Picture: Why Plumbing Matters to Public Health and Daily Life

Plumbing is the quiet infrastructure that turns buildings into livable spaces. Safe water supply prevents disease, and reliable drainage protects indoor air quality by keeping sewer gases isolated and controlled. In the United States, building codes establish the minimum safety bar, but the true value appears in outcomes: fewer leaks, fewer mold incidents, and comfortable, functional spaces that support work, learning, and rest. Understanding Plumbing Systems and Their Role in the USA is not just a technical exercise; it is a public-health narrative supported by engineering.

Consider daily usage patterns. Indoor water demand often ranges around dozens of gallons per person per day, spread among bathing, laundry, toilets, faucets, and dishwashing. Small inefficiencies in fixtures or leaks—think a worn flapper valve or a pinhole in a copper line—scale into significant waste over months. Drainage has its own choreography: pipes must slope gently so gravity can move wastewater without allowing solids to stall. Vents supply air, stabilizing pressure, and water seals in traps block odors. When these parts work together, the system is invisible; when they falter, occupants notice instantly.

Plumbing also intersects with energy and resilience. Water heater setpoints influence both scald risk and energy bills; many households target around 120°F to balance hygiene and efficiency. In regions with freezing winters, insulation and heat tracing prevent burst pipes. Drought-prone areas lean on water-efficient fixtures and leak detection to stretch supplies. These regional nuances matter because the same design that thrives in a coastal climate may struggle at high altitude or in subzero cold.

– Public health: containment of waste, prevention of cross-connection, and protection against legionella through temperature control

– Resilience: freeze protection, seismic bracing, and storm backflow safeguards

– Efficiency: right-sized piping, pressure management, and leak monitoring

– Comfort: steady pressures, quiet drains, and consistent hot water delivery

The takeaway is simple but powerful: a building’s plumbing is a living system, shaped by codes, climate, materials, and the people who use it. When treated as infrastructure instead of an afterthought, it delivers reliable service for decades.

Homes vs. Workplaces: Scale, Loads, and Design Culture

Residential and commercial buildings share fundamentals—potable supply, drain-waste-vent paths, and fixtures—but scale and risk profiles diverge. An Overview of Residential and Commercial Plumbing in the United States reveals how occupant counts, fixture density, and uptime demands drive different design decisions. A single-family home might prioritize quietness and easy maintenance, while a hospital, school, or warehouse prioritizes redundancy, accessibility, and strict water safety protocols.

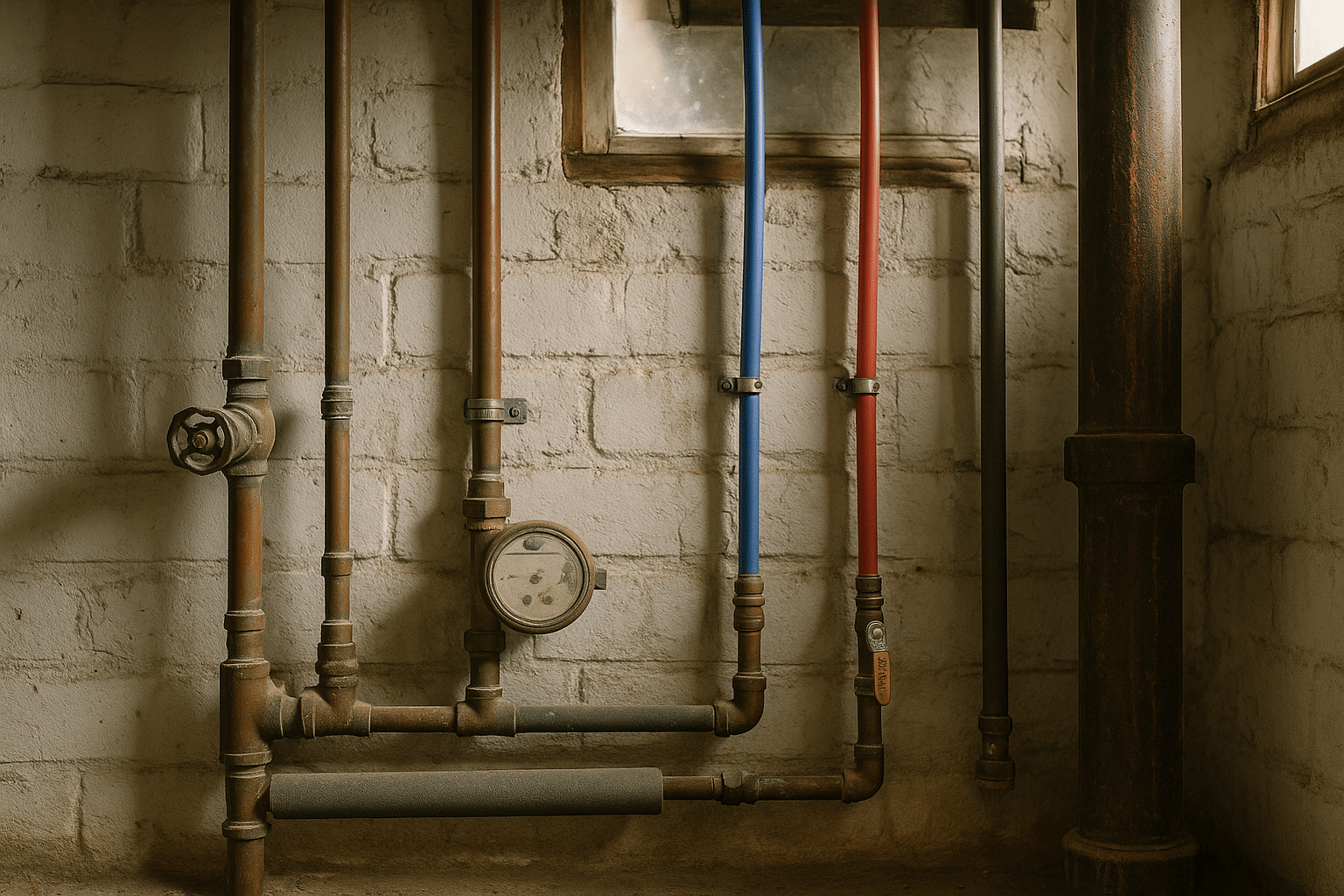

In homes, fixture groups are clustered near kitchens and bathrooms to streamline runs and reduce pressure losses. Materials like copper, CPVC, PEX, PVC, and cast iron are common, chosen for budget, noise, and temperature tolerance. Water heaters may be tank-style or tankless, sometimes with recirculation to shorten wait times for hot water. Drain lines rely on correct slope—often around a quarter inch per foot on small-diameter branches—to move waste smoothly, and vents connect to maintain neutral air pressure.

Commercial systems multiply these concerns. Higher fixture counts require trunk-and-branch or manifold strategies that balance pressure across many simultaneous users. Backflow prevention becomes non-negotiable where irrigation, process equipment, or chemical feed systems exist. Large buildings segment pressure zones by floor count, and maintenance teams track valves and meters methodically so that service work can isolate a wing without shutting down an entire facility. Grease interceptors, oil-water separators, and dedicated laboratory drains often enter the picture, each with inspection and cleaning schedules.

– Homes: shorter pipe runs, fewer simultaneous demands, focus on cost control and comfort

– Offices and retail: predictable peak loads, recirculation for hot water, accessible shutoffs

– Healthcare and labs: stringent cleanliness, redundant heaters and pumps, robust backflow control

– Food service: grease management, frequent maintenance, temperature-verified sanitation

Beyond hardware, there is a difference in culture. Homeowners may make incremental upgrades—a new low-flow showerhead, a pressure-reducing valve, or a leak detector near the heater—while facility managers rely on preventive maintenance plans and documented inspections. In both arenas, the path to reliability is the same: clear design intent, appropriate materials, and disciplined maintenance.

From Meter to Main and Back Again: Supply, DWV, and Pressure

Every plumbing system tells a two-part story: supply delivers clean water under pressure, and drainage returns wastewater to treatment by gravity. How Plumbing Systems Manage Water Supply and Drainage Across the USA depends on three controllable elements—pressure, slope, and isolation. When these are set correctly, fixtures behave predictably, water quality remains protected, and maintenance becomes straightforward.

On the supply side, municipal water typically arrives at a meter with a shutoff. A pressure-reducing valve may follow if street pressure is high, aiming to keep building pressure in a comfortable zone, often near 40–60 psi. Branch lines feed fixtures, and recirculation may be used in longer runs to minimize hot water wait times. Cross-connection control is critical: air gaps, vacuum breakers, and backflow preventers stop contaminants from siphoning into potable water. In taller buildings, booster pumps and hydropneumatic tanks maintain pressure on upper floors, organized by zones to avoid over-pressurizing lower levels.

Drain-waste-vent (DWV) systems reverse the logic: gravity is the engine, and air is the stabilizer. Branch lines carry waste to stacks, which connect to building drains and ultimately the sewer or a septic system. Vent pipes admit air so that traps can hold their water seals; without vents, siphonage could empty a trap and allow sewer gas indoors. Cleanouts provide access for augers or jetting tools, which is indispensable when fats, oils, or wipes cause blockages.

– Supply control points: meter, main shutoff, pressure regulator, water heater, isolation valves

– Safety barriers: backflow preventers, air gaps, thermal expansion tanks, mixing valves

– DWV essentials: trap seals, venting, cleanouts, proper slope, gas-tight joints

Regional conditions complicate the picture. In cold climates, lines route through conditioned spaces or are insulated to prevent freezing; hose bibbs may be frost-free types with vacuum breakers. In arid zones, water budgets push toward high-efficiency fixtures and leak analytics. Coastal and flood-prone areas sometimes add backwater valves to mitigate sewer surges during storms. The principles remain constant—manage pressure, maintain slope, and protect isolation—but the implementation adapts to place and purpose.

Materials, Components, and Design Choices That Matter

Good plumbing blends durable materials with thoughtful layout. Key Components and Considerations in U.S. Plumbing Systems start with pipe selection: copper handles heat well and resists UV, PEX offers flexibility and freeze tolerance, CPVC is common for hot and cold distribution, PVC serves many drain lines, and cast iron dampens noise in stacks. The correct choice balances cost, sound control, temperature limits, and ease of installation, all aligned with local code approvals.

Valves are the hands of the system. Ball valves give reliable quarter-turn shutoff, gate valves appear on some legacy mains, and check valves prevent reverse flow where pumps or elevation differences exist. Thermal expansion tanks protect closed hot-water systems from pressure spikes, while thermostatic mixing valves temper hot water to reduce scald risk at points of use. Trap seals—often 2 inches of water depth—block odors, and vents maintain those seals by preventing negative pressures.

Design details turn theory into performance. Drains commonly use a slope near 1/4 inch per foot for smaller diameters, while larger pipes can run slightly flatter due to higher flow velocities. Water heater settings around 120°F balance scald prevention with hygiene, though some facilities employ higher storage temperatures paired with mixing to manage microbial risk. Recommended building pressures often land between 40 and 60 psi; pressures above that may call for regulation, and pressures below that may require boosting.

– Pipe selection: align temperature, noise, and budget with code-compliant materials

– Valve strategy: isolate fixtures and floors to simplify maintenance

– Safety devices: backflow prevention, mixing valves, and expansion tanks for stability

– Layout: minimize dead legs, right-size pipes, and maintain accessible cleanouts

Quality control matters as much as components. Pressure tests verify that supply lines hold steady with no leaks. Drain lines are often tested with water or air for tightness before walls close. Insulation reduces heat loss on hot-water runs and controls condensation on cold lines. Acoustic considerations—especially in multi-family housing and hotels—favor cast iron or sound-treated assemblies for stacks. Finally, documentation seals the deal: as-builts, valve tags, and maintenance logs turn a complex network into a navigable map for future work.

Putting It All Together: A Practical Conclusion for Owners and Operators

Plumbing serves people first. Whether you manage a single home or a multi-building campus, your goals are similar: protect health, sustain comfort, and control costs without sacrificing safety. The path forward is methodical. Start with knowledge—an inventory of valves, pipe materials, heater types, and known trouble spots. Build a maintenance rhythm around inspections, filter changes, and seasonal checks, and treat water quality and pressure like vital signs that deserve regular readings.

Action steps you can begin today:

– Find and label the main shutoff and critical isolation valves

– Measure static water pressure and install regulation if it trends high

– Set water heater targets thoughtfully and verify mixing at fixtures

– Inspect visible piping for corrosion, stains, or insulation gaps

– Schedule routine cleaning for grease traps or separators where applicable

– Add leak sensors in high-risk areas near heaters, laundry, and mechanical rooms

Budgeting is easier when surprises are reduced. Group upgrades to minimize downtime: for example, replace aging shutoffs during a planned fixture renovation, or add insulation while a ceiling is already open. Calibrate expectations about service life—elastomers may age faster than metal pipes, and water chemistry can shorten or lengthen those timelines. Permits and inspections may be required for significant work; engaging licensed professionals keeps projects compliant and safer.

Communication also matters. For households, that means teaching everyone how to turn off the water in an emergency. For facilities, it means documenting procedures, logging incidents, and training staff in basic response. Over the long run, these habits protect your investment and the people who rely on it. Think of your plumbing as a small utility that you steward: with steady attention and informed choices, it will deliver clean water, quiet drains, and dependable service year after year.